HOJOOY

Ball Bearing Slide

Heavy Ball Bearing Slide Use – For the Best Support

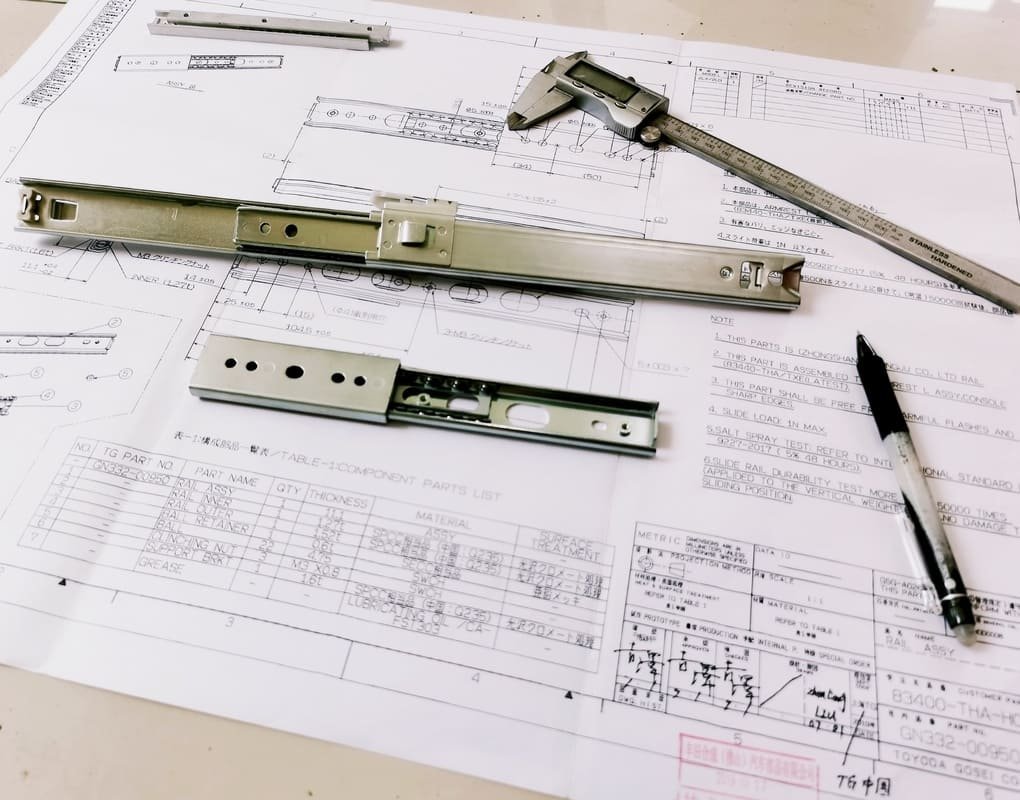

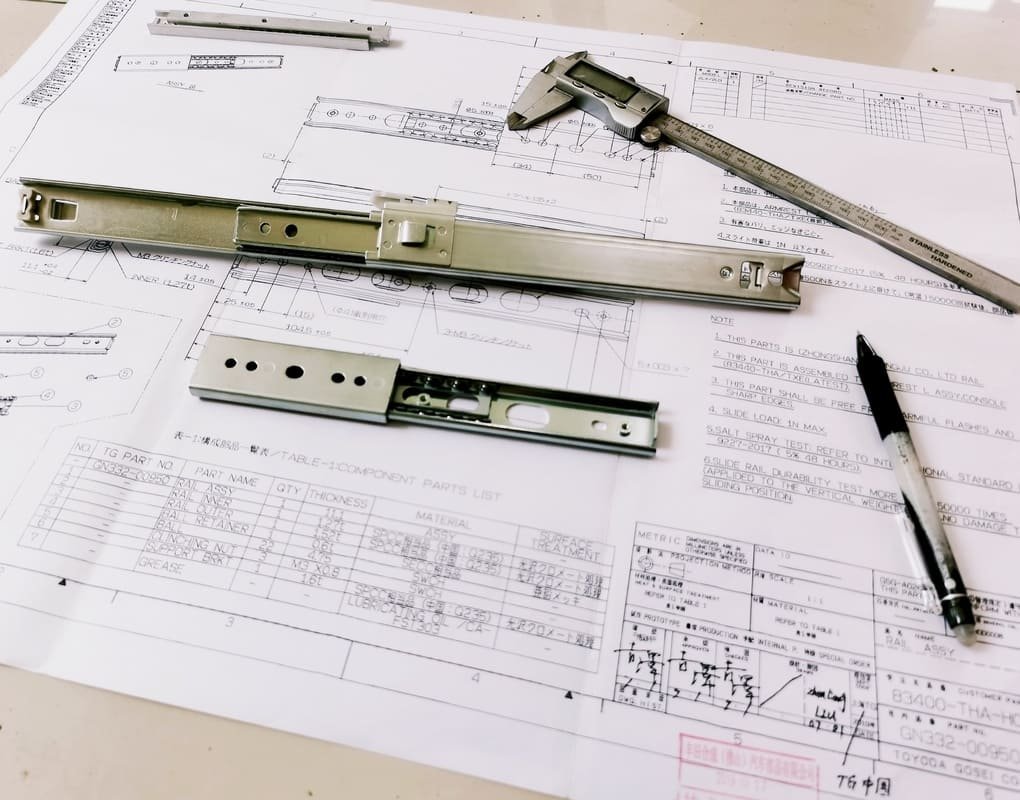

A ball-bearing drawer slide is an excellent choice for supporting drawers and shelves that are designed to support heavy loads. HOJOOY provides half extension and full extension ball bearing slides to suit your needs.

Ball Bearing Slide Information

Ball bearing slides use rollers in place of ball bearings to facilitate the Telescopic motion. They are composed of three parts with two sets of ball bearings that connect between the members. As the mechanism grows the ball bearings permit members to slide over the other until it is fully extended.

Table of Content

- Configuration

- The mounting process of Ball Bearing Slides

- Side-Mounted

- Types of Ball Bearings Slides

- Conclusion

Configuration

The reason why companies prefer to buy ball bearing glides from Hojooy is for their ability to support heavy weights. This makes them ideal for use in large storage cabinets, filing and archival systems and in factories.

---------

HOJOOY Ball Bearing Slide MANUFACTURER

Slides for drawers with ball bearings are able to live up to their name because they feature ball bearings. Some of them provide one-way travel. Others, like ball-bearing drawer slides, provide two-way travel. In any case, they all have ball bearings. Slides for drawers with ball bearings are made of multiple rails. The rails are made of ball bearings, not wheels. This collection of Ball Bearing Drawer Slides is available in mild steel as well as stainless steel grade 304 that is ROHS fully compliant. These stainless versions of the slide are suitable to be used in extreme environments and can be used for use in food processing facilities.

The types of Ball Bearing Slides

At Hojooy, we provide convenient and lasting industrial solutions through our range of ball bearing slides. These models use ball bearings as a more efficient alternative to roller slides without creating any kind of noise or jerks during motion.joi

Heavy Duty Drawer Slide

Soft Close Drawer Slide

Cabinet Drawer Slide

Electrical Ball Bearing Slide

Automotive Ball Bearing Slide

Furniture Drawer Slide

It’s a fact that ball sliding drawer slides that are bearing are very popular. If you compare them to wheel-based slides, they provide an easier operation, which allows them to be used more easily.

Ball sliding drawer slides that are bearing are distinguished with the help of balls. They are made up of rails that have small balls, which are usually stainless-steel ones. If you pull the drawer, it will move over the balls. Although every ball-bearing drawer slide comes with balls, the manner the way they are mounted can differ. Slides with ball bearings come in a variety of mounting styles and some of them comprise the ones below.

Installation Classification of Ball Bearing Slide

Side-mounted ball drawer slides with bearings are the most popular. They comprise a pair of rails, each one of which has a set of balls. The name implies that side-mounted ball-bearing drawer slides are set on the sides. It is necessary to place every rail on the side where the drawer is mounted on. Some models provide one-way travel, while others allow two-way travel. In any case, the ball-bearing drawer slides that are mounted on the side are installed on the sides.

Bottom-Mounted

Although they aren’t as widespread as side-mounted drawer slides, a different type of drawer slide with ball bearings that are bottom-mounted. Bottom-mounted ball bearing slides appear like the side-mounted versions. They’re made up of two rails.

Center-Mounted

The slide is mounted on the inside of the ball bearing., too. The ball bearing slides mounted at the center is installed in the lower part of the drawer. But, they’re not identical to bottom-mounted ball-bearing drawer slides.

Center-Mounted

Bottom-mounted ball bearing slides for drawers comprise two rails in contrast, center-mounted ball bearing slides generally comprise a single rail. When you have center-mounted ball-bearing slides, only one rail is mounted to the bottom part of the drawer.

Cost of production and delivery

We keep our costs of production and delivery under control by adhering to the basic steps listed below.

Step 1

In this stage, the ideal ball bearing slide model is identified from the catalogue. If unavailable, a bespoke model is designed and prepared for prototyping.

Step 2

This is the second stage where the approved ball bearing slide design is produced in the agreed quantity by adhering to the material and quality specifications.

Step 3

Every item is packed at our warehouse and is stored until it is ready for delivery to the client.

STEP 4

This is the final stage where the order is shipped to the client according to their preferred mode of transport.

Types of Ball Bearings Slides

Want to know how we manufacture the best ball bearing slides in the industry? Learn about our simple manufacturing process:

Conveyor & end cap bearings

Our single-piece Thrust Bearing assemblies can handle greater thrust loads axially within one direction, at moderate speed, and with only a small radial load.

Thrust bearings

Our single-piece Thrust Ball Bearing assemblies are able to handle higher thrust loads axially within one direction, at speed of moderate, and with only a small radiation load. They are available in the standard inch and the metric size. All information is based upon racers made of acetal with stainless steel or glass balls. Other materials and sizes are also available.

Flanged bearings

A Perfect Match A Perfect Fit – We stock thousands of non-standard as well as standard parts on hand – both metric and inch sizes. This means faster delivery and lower interruption to your machinery. There’s more than one factor that makes us stand out. Our expertise and reliability are unmatched in the market from finding the ideal replacement part.

Radial bearings

Our ball bearings made of plastic are ideal for different uses, such as washing down areas in which equipment is often in a state of constant moisture and is susceptible to rust using conventional bearings. In corrosive environments, where bearings are exposed to chemical abrasiveness are also ideal for ball bearings made of plastic. When you have to move at a relatively low RPM and load the largest machinery, Monroe has the right bearing to keep your business running smoothly. Even if the equipment is situated in a way that makes access to lubrication for bearings difficult, this is not an issue because the bearings we use are self-lubricating.

Conclusion

Also known as ball-bearing+- drawer slides, they are among the most commonly used kinds of drawer slides. If you pull the drawer that is attached to it the slide will glide over the balls. Slides with ball bearings prevent drawers from directly touching the furniture on which they are mounted.

Have you worked with international clients?

Despite being relatively new in the industry, we have built close relationships with the most renown brands in the world, for example, Dell in the electronics industry and Honda in the automotive industry.

How do you transport orders?

We offer multiple delivery and transport options to our clients due to our excellent relationships within the transport network.

Is there a minimum order I should place?

At HongJu, we believe in serving all clients, regardless of their order size. Our flexible manufacturing processes enable us to complete large and small orders equally well.

How long does it take to receive my order?

Each order is different and requires a different delivery time. However, we provide standard and premium delivery options depending on the urgency.

Conclusion

Also known as ball-bearing+- drawer slides, they are among the most commonly used kinds of drawer slides. If you pull the drawer that is attached to it the slide will glide over the balls. Slides with ball bearings prevent drawers from directly touching the furniture on which they are mounted.

They’re a great option for drawers that do not need to support a significant amount in weight. They can be used in conjunction with drawers that self-close. Slides equipped with ball bearings tend to be stronger and offer greater weight capacities. The majority of soft-closing and self-closing drawers are equipped with ball-bearing mechanisms.

Solutions

PROFESSIONAL MANUFACTURER

If you have any questions on your mind. Please, feel free to contact us.